Differential Pressure Flow Meter

Measuring flow using the Differential Pressure (DP) method is one of the most common technologies for measuring flow rates in pipelines. This technology is used in DP flow meters.

Flow or Flow Rate

Flow theory is the study of fluids in motion. Any substance that can flow is considered a fluid. Therefore, this term applies to both liquids and gases. Precise control and measurement of flowing fluids in pipelines require a thorough technical understanding and are of great importance in most process industries.

How DP Flow Meters Work

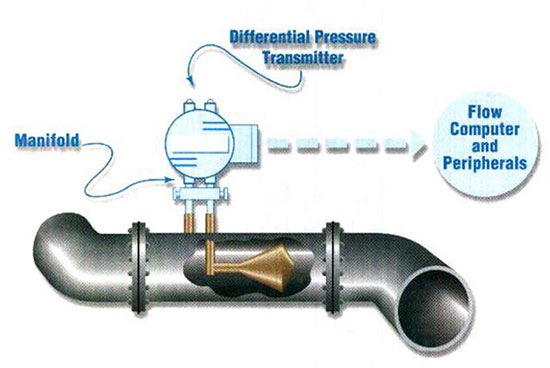

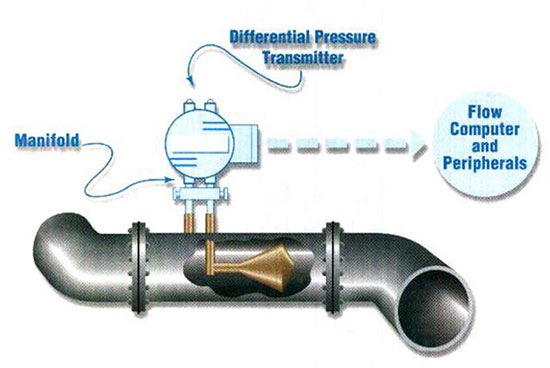

The differential pressure flow meter is one of the pressure measurement devices and its operation is based on creating an obstruction or barrier in the fluid flow path within the pipe. This creates a static pressure difference above and below the device, which is called the differential pressure (DP). (referred to as DP) and is measured. It serves as the basis for determining flow rates. Differential pressure meters, or DP flow meters, are very popular, and it is estimated that approximately 40% of industrial flow meters currently in use are of the DP type with an orifice plate as the primary element. DP flow meters are used for measuring the flow of a wide and varied range of fluids, from liquids and gases to highly viscous fluids. The DP flow meter is one of the most popular precision measuring instruments, and this popularity is due to its simple design and low cost. The primary element, which is placed in the fluid path and creates an obstruction in the pipe's path, causes the static pressure difference in the DP flow meter. This pressure difference is measured by a secondary element, which is a differential pressure transmitter. A third element in the system is needed to assist with the measurement, including impulse piping and connectors that direct the upstream and downstream pressures towards the transmitter. By creating a carefully engineered obstruction in the pipe's path, Bernoulli's equation can be used to calculate the flow rate because the square root of the pressure drop created at the obstruction is proportional to the flow rate. There are several important considerations in flow measurement using differential pressure flow meters::

Ensure that the impulse lines are not clogged with particles and deposits.

Ensure proper impulse line orientation (it should be in a manner that prevents gas density in liquids and vice versa).

Ensure that periodic calibration does not compromise accuracy.

Types of Primary Elements in DP Flow Meters

Orifice Plate

Single and Multiple-Orifice Pitot Tubes

Venturi Tubes

Flow Nozzles

Cones

Transmitter Selection in DP Flow Meters

There are two types of pressure transmitters used in differential pressure flow meters. The first type is a traditional DP pressure transmitter that only measures the differential pressure and has no auxiliary parameters. The second type is a multivariable transmitter. The multivariable transmitter is a DP pressure transmitter capable of measuring multiple separate process variables, including differential pressure, static pressure, and temperature. When used as a mass flow transmitter, these values can be used separately to compensate for changes in density, viscosity, and other flow parameters.

Applications of DP Flow Meters

Product Consistency: For products that are batched and blended, precise ratios of constituents are required. DP flow meters help in accurately measuring and controlling gases and liquids.

Production Efficiency: Measuring and controlling flow rates, including DP flow (flow rate), accounts for a significant portion of process control variables, from batch control at the beginning of a production line to product finishing at the end of the line, impacting production efficiency.

Control of Process Variables: Processes often have multiple input variables, including flow control (flow rate). Controlling these variables, including flow control, leads to the production of high-quality products.

Safety: Measurement using the Differential Pressure method in DP flow meters prevents many safety hazards. These include preventing tank overflow and controlling reactors.

History of DP Flow Meters

Flow measurement has been around for thousands of years, dating back to when the Egyptians decided to measure agricultural products based on the relative height of the Nile River's flood. Later, Roman engineers designed channels to hold water in cities. Users would measure the amount of water consumed using a well or orifice placed on the dam. Markings on the aqueduct walls, flow orifice, or an estimate of the consumed flow rate were provided. The discovery of the law of gravity in 1687 by Newton enabled mathematicians and physicists to transform motion and force theory into formulas, eventually leading to the development of flow measurement methods.